Oxford Sensors Ltd

Unit 11, Arena 14

Bicester Park

Charbridge Lane, Bicester

Oxfordshire, OX26 4SS

United Kingdom

Copyright © 2021 Oxford Sensor Systems Ltd. All rights reserved

Oxford Sensors announces a new integrated

head and controls for Submerged Arc Welding

Oxford

Sensors

Ltd

(OSL),

Bicester,

UK

announces

the

release

of

a

new

fully

integrated

system

for

tandem

or

triple

submerged

arc

welding.

The new system incorporates several innovations:

1.

A

completely

new

weld

head

design

which

is

easy

to

set

up

and

adjust,

and

which

integrates

up

to

three

torches

together

with

flux

delivery and recovery, laser seam tracking and video camera.

2.

Modular

design

for

ease

of

using

the

key

components

in

several

mill

locations.

The

new

head

has

already

been

installed

on

several

pipe

mill

applications.

For

spiral

pipe

offline

ID

welding,

it

can

be

mounted

on

a

new

OSL

boom-end

frame

incorporating

horizontal

and

vertical

slides

with

space

for

up

to

three

wire

feeders.

For

spiral

pipe

OD

welding

or

other

similar

applications,

the

new

head

can

be

mounted

on

an

OSL

slide

assembly

together

with

up

to

three

wire

feeders for single, tandem or triple arc operation.

3.

A

new

integrated

control

system

allows

all

parts

of

the

system

operation

to

be

controlled

from

a

single

station.

The

new

control

station

can

be

used

for

simultaneous

control

of

ID

and

OD

weld

heads for spiral pipe offline welding from a single station.

4.

The

new

system

is

based

on

a

network

architecture

allowing

it

to

be

easily

used

with

welding

power

sources

from

leading

manufacturers.

According

to

Bob

Beattie,

of

OSL,

“Over

the

last

twenty-five

years,

we

have

developed

a

lot

of

experience

in

pipe

mill

welding

and

other

similar

applications.

So

when

we

had

the

opportunity

to

put

that

experience

to

work

in

designing

this

new

system

we

were

very

excited

by

the

possibilities.

After

a

lot

of

intensive

effort

in

design

and

on

proving

trials,

we

are

very

pleased

with

the

results.”

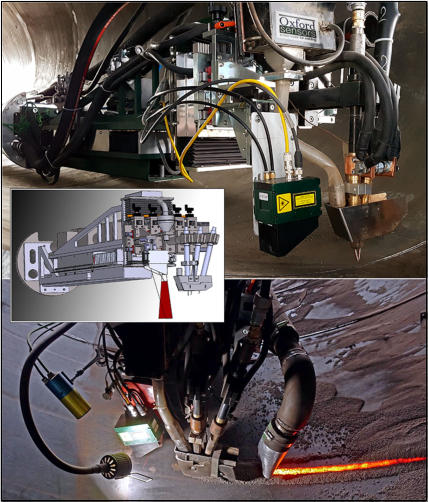

The photo shows the design superimposed over one of the heads mounted for spiral offline ID welding.